http://www.goukulelecrazy.co.uk/

Messing about online, I stumbled across this; http://www.youtube.com/watch?v=ECYs-jTZpjA

and I liked the sound of it.

Some of them are works of art in themselves, eg; http://boraborarealtor.com/tahitianukulele.html

Basically, the Tahitian ukulele is an 8 stringed instrument carved out of a single piece of wood. The strings are fishing line, in four courses. Each "pair" is in fact one length of line doubled back on itself. The tuning is GCEA as in the Hawaiian uke, but the it C and E are one octave higher than in the more familiar instrument. The sound is amplified by the bridge transferring the string vibrations to a wooden sounding-board behind which is a conical or bowl-shaped cavity, wide at the front, tapering to a narrow hole at the back. This seems strange when you are used to instruments with the hole in the front, but it's the same principle as the banjo, with wood instead of skin.

I thought I might like to try one, so I did an online search of my local music shops. None seemed to stock Tahitian ukes, so I tried further afield, but there does not seem to be a supplier anywhere in the uk.

Then I saw a rather more basic version at http://www.instructables.com/id/Good-enough-for-the-bush-Australian-version-of-Tah/

This made me wonder if it might be possible to build one myself.

I wasn't much good at woodwork at school, but my teapot stand supported the teapot, my stool is still standing, though I wouldn't like to sit on it, and my "what-on-earth-is-that" fell apart. I don't know what it was meant to be. This is a sketch of it;

Any suggestions?

I wouldn't like to sit on that, either!

The last time I tried woodwork at home was when the plastic seat of the kids' garden swing broke. That would be over 20 years ago. The swing is no more, but the seat lives on, just adding a bit of colour to the patio, don't you know.

I think I would be prepared to sit on that if necessary.

Anyway, I still had the rest of the plank in the garage, so I took some measurements and found that if I cut it in half and stuck the halves together back to back, I had about the right length of wood to make a small version with the scale length of a "concert" ukulele, rather than that of a tenor, as the genuine article seems to be.

I thought I might give it a try, just as a "proof of concept" exercise, so I didn't want to spend anything much on it. I've got some basic hand tools, plus an electric drill & a hand-held electric saw. I also have a chisel.

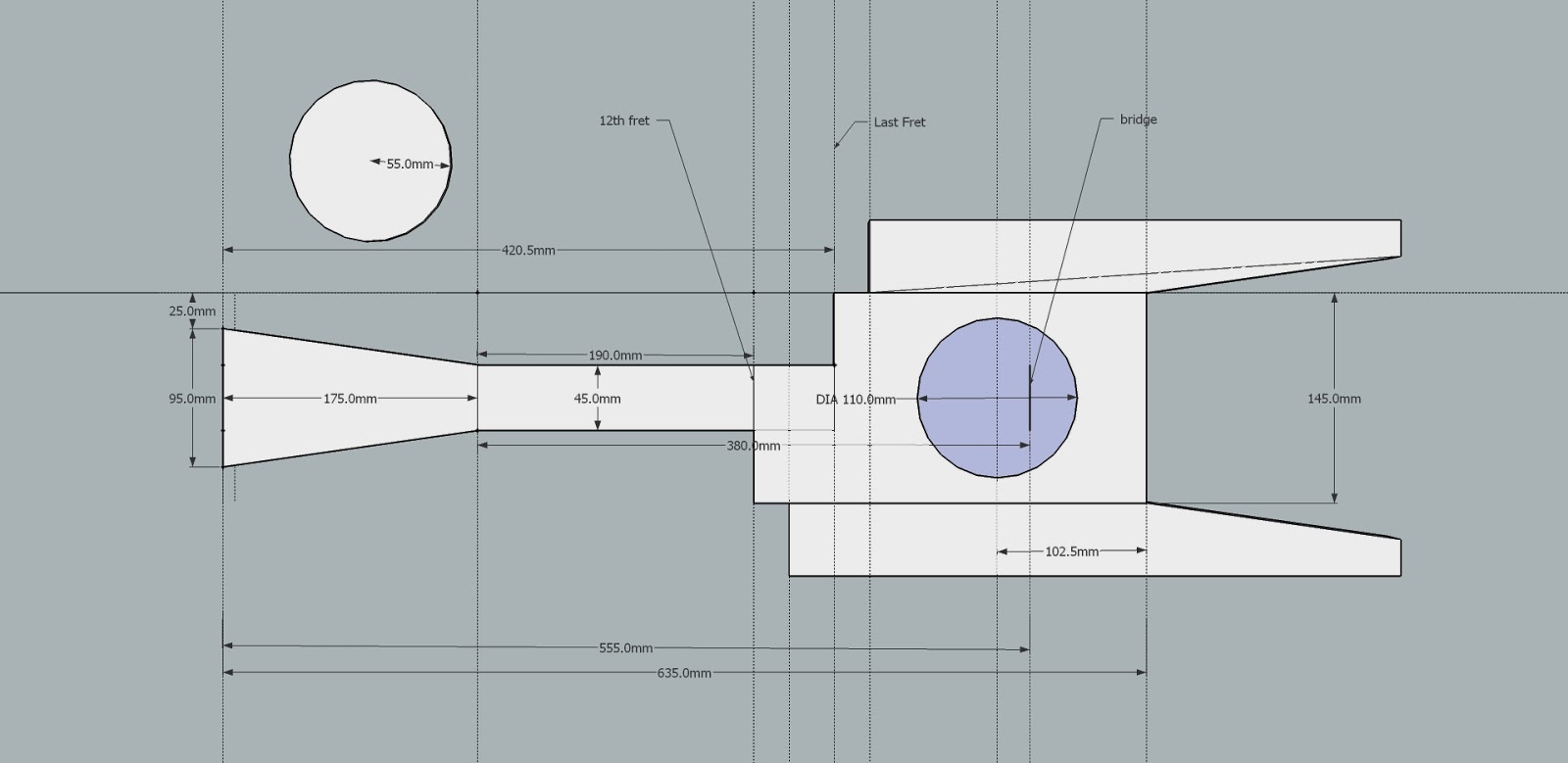

I downloaded Google's "Sketch Up" which turns out to be a pretty easy to use drawing programme, allowing 3D viewing of the object being drawn. I never did technical drawing at school, but this CAD-type program is fairly easy to grasp, and with a little practise I was able to design my instrument, complete with measurements.

In Sketch Up, I started with the basic plank shape, and did all the sticking and cutting in that virtual environment. This confirmed my idea that I would be able to use off-cuts from alongside the neck to widen the body as on the real Tahitian uke.

I could then shape the body in a more elegant fashion, and make something resembling the real thing;

Then I set to on my plank. First I cut it in half, and stuck the two halves together one on top of the other, to give me the thickness I required. Then I copied the measurements from my plan onto the face of the wood with pencil & ruler. I borrowed an old pair of compasses which have been lying around for thirteen years or so, that being approximately how long it is since my youngest son took his GCSEs. These I used to mark out the circles on the front and rear. I thought it would be difficult to excavate the tapering hole, so I decided to tackle this first. I don't have hole cutters, and I wasn't going to spend anything, so I'd have to do it the hard way. I own a chisel. I started on the back, so if I made a mess it wouldn't matter too much, and I could learn from it. Using a Stanley knife I cut into my pencil ring, then chiseled about inside that circle until I had an indentation. I think I may have drilled a hole right the way through at that stage as well. It wasn't very easy, and it wasn't very circular, (here seen at a later stage)

so when I'd cut about 5mm into the back, I turned over and assaulted the front, a little more carefully. It was slow going, and the result was very rough. I decided to use my electric drill to honey-comb the area, going deeper in the centre than at the edges, then chisel out the rest. This saved a lot of time, but the finish was poor. I've got a conical burr bit for my drill, and also a flap sander bit, so I used those to hack out a bit more wood and smooth it down a bit. It's still rough, but it won't be visible.

Having cut my cone, I thought the rest of the construction may be possible. I'd got a box of Chocolate Gingers for Christmas, and they came in a square wooden box with a pleasing design on the lid, so I thought I'd use the lid for the sound board, leaving it square, resting on top of the hole, no need to find a piece of thin wood, no need to cut a circle.

I cut the rough shape of the head and neck using my electric jig-saw. Because the head has to be angled back to hold the strings down in the nut, I had to cut that profile with an old hand saw. It isn't very sharp, having been used on a lot of conti-board 30 years ago, and it took a few sessions for me to cut off the wedges top and bottom, and I left some very deep saw marks. Never mind, it's supposed to be a bit rustic. I was able to use my jig-saw to cut the neck profile, which I then rounded off with my burr/flap wheel combination. I tried to clean it up with the chisel, but it just shredded the wood, so I finally gave in and bought some new chisels. More importantly, though I didn't realise it until later, I bought a sharpening stone. Even the new chisels didn't cut very well; I hadn't realised that they're not fully sharpened when you buy them. Once I'd honed them up, I was able to carve the soft wood quite smoothly (for me). I could even use them to smooth out some of the hand-saw marks on the head.

There were some corners to cut off the body, they could wait until I'd stuck the "wings" on. And then I decided that wings would be an added complication, not required for a prototype such as this, so I cut the curves off the shoulders and tail of the body, and rounded off the edges. There's a funny little feature on the upper bout of Tahitian ukes, and no one seems to know why, but its a kind of reduced thickness ledge, so I used the burr/chisel/flap wheel method to make one of those.

That wretched knot made it a bit difficult.

Around about this time, I began to think that this thing might get finished, so I started looking in to the hardware required. There are people who have made their own tuning pegs. There are people who have used ordinary wire, or pared-down toothpicks for frets. I found a set of ukulele frets, cut to size, on the internet for £1.75 including postage, so why fiddle about making my own? There was no way I was even going to attempt to make eight identical accurate conical tuning pegs with conical holes to match, so I ordered a set of mandolin tuners, the cheapest I could find that came with all the screws and grommets.

I knew I needed to be pretty careful about fret positions, so I did a bit of research. There are a number of places on the net where you put in your scale length, and the required fret positions are displayed. There's one towards the bottom of this page;

I thought that the results to 3 decimal places in millimetres were probably beyond my reach as a wood-worrier, but I thought I could maybe put those dimensions onto a Sketch Up fretboard & print them to size, then copy them to the instrument. This didn't work, as I couldn't find a way to get Sketch Up to print actual size. So, I turned to another free programme, part of "Open Office" - Open Draw. This did the job! I printed out my fretboard spacings on A4, then pinned the sheet to the wood, and used pins to prick through the paper marking the fret positions. This worked too! I then used my metal rule & Stanley knife to cut guide slits at each fret position, including the nut position. I had decided to use a "zero fret" because I didn't think I'd be too good at cutting a nut accurately eight times. Once scored, I then used a junior hacksaw to cut the slots. I'd had a bit of a practice on some of my off-cut wood, and I'd found that if I opened up the top of the fret slot a bit with a slightly thicker saw blade, the fret went in quite evenly. Then I found I had a triangular cross-section needle file that did the job even better - just a couple of strokes of the file cut a bevel which guided the fret into the slot nicely. My internet research told me that I had to have a special fret hammer, and tap carefully in a certain way, and even then some frets would be temperamental and need special attention. Some of my slots were a bit loose, and the wood I was using was soft pine or similar, so I decided I would have to rely on glue anyway, so one at a time, I pushed each fret into the slot a bit, then covered it with a bit of discarded wood, which I then whacked with a perfectly ordinary hammerfore.

What's a hammerfore?

Knocking nails in!!

It worked. The frets sat obediently in their slots. I trickled superglue into each end of each slot. Seemed ok.

Some of them stuck out a bit at the edges, so I filed them back.

I used Open Draw again to print a template for the holes in the head to take the tuning pegs, and drilled those through. The pegs clicked neatly into place, much to my surprise.

I made a nut from a strip of unnamed hardwood that I picked up at a local timber merchants. Because of the zero fret, all I had to do was glue the nut in place, and cut slots deep enough to guide the strings onto the fret. I printed out the desired spacings from Open Draw, then I used my junior hacksaw again, but placed a sliver of paper over the fret, so that I knew when I'd cut deep enough. That worked reasonably well, but I chipped a bit off the wood. That's because I was cutting into the edge, across the grain. I'd seen a trick somewhere, of using baking powder and superglue to reconstruct bone nuts, so I'd had the foresight to collect some of the dust from sawing & sanding, which I used with superglue to rebuild the chipped part. After it set, a bit of needle-file & sanding brought it back into shape, and I was able to re-cut the two affected slots. Looking at it now, I really can't tell which is the real wood, and which the fake.

I made a bridge from the same bit of wood. That also needed slots cutting, but not so deep. They are only there to retain the string spacing.

At this point, I tried loosely assembling the instrument. I clicked the tuning pegs into position, but didn't screw them down. I balanced the sweety-box top over the hole, and stood my bridge on it. Then I stretched a bit of fishing line from one tuning peg to the bridge. As I had feared, the box top resting on the surface of the wood was too thick. The bridge had to be a certain height to ensure that the string could clear the edge of the box top, and the combined heights of top-plus-bridge would make the string stand too far off the fret board. This should have been obvious, as there is no fret board as such; the frets are set into the plank surface, so the fretboard is flush with the instrument top. If the neck was angled back I might have got away with it, but as the whole thing is flat, I had to resign myself to cutting my decorative box top, and also to cutting a lip around the hole in the top, and making the two fit together. I drew a circle on the back of my box lid, then cut as close to it as I dared with various saws, finishing up by rasping & filing & sanding as close as I could to the pencil line. I cut the lip with my trusty chisels. I couldn't get it perfectly even in depth, but with small adjustments here and there, I got a reasonable fit.

I thought I'd try to copy the design from the box top onto a piece of paper and use it to decorate the headstock, having edited it to distort the shape to fit. It sort of worked.

To attach the strings, I used a couple of "U" shaped nails at the bottom end, so each pair of strings would have its own leg to be tied around. That worked, but the wood was so soft that where the strings pass over the end, they were cutting in. So I decided to protect the wood, and what could be better than the lid off a soup can? I cut it a bit, bent the sharp edges back, and, nailed it to the end. I think it actually improved the appearance somehow.

I tuned everything up, and was pleased to find that there were no problems with the frets, and the bridge was easy to position to give good intonation. I was disappointed at how quiet it was, but the reasons were fairly obvious - the cavity was small, and the sound board was; a/ a bit thick, b/ a bit soft, and c/ covered with paper. Nevertheless, it played. The G & A strings were particularly quiet. This was probably due to the low tension on those strings. The thin fishing line just didn't need much winding to reach the required note. So I ordered some thicker line, and the balance was improved. The new line is red, the old is a sort of dirty green colour.

The appearance - well, largely due to my decision not to add the "wings", it looks like something you might paddle a canoe with.

The sound is a bit like a toy instrument. It has fairly good sustain, but is quiet - rather like an electric guitar unamplified.

This partial success has encouraged me to try to build a longer scale instrument, equivalent to the tenor ukulele scale length. I'll need to do another blog for that.

The King Casino Archives - Hertzaman

ReplyDeleteThe King Casino Archives, including herzamanindir.com/ news, septcasino.com articles, 바카라 videos, address, gaming info, The King Casino & 1xbet 먹튀 Hotel in Henderson, NV is one of the newest hotels and motels www.jtmhub.com on